The creation of an ergonomic mouse is a precise process that blends traditional craftsmanship with advanced technology. It begins with sculpting a physical mold that meets ergonomic standards. This mold is then scanned using a 3D scanner, capturing its shape in a digital format that serves as the foundation for further design work.

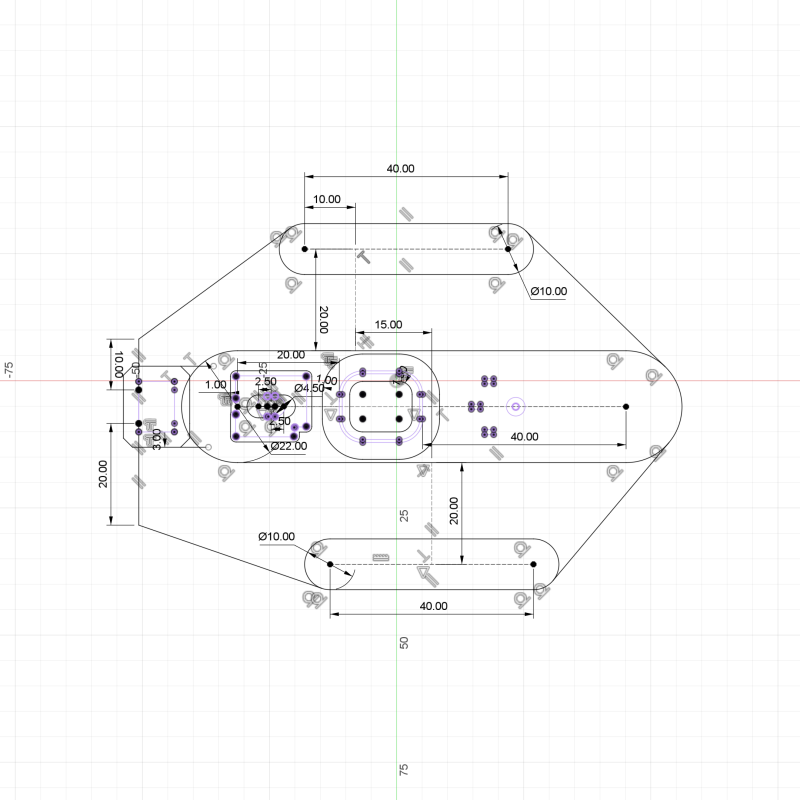

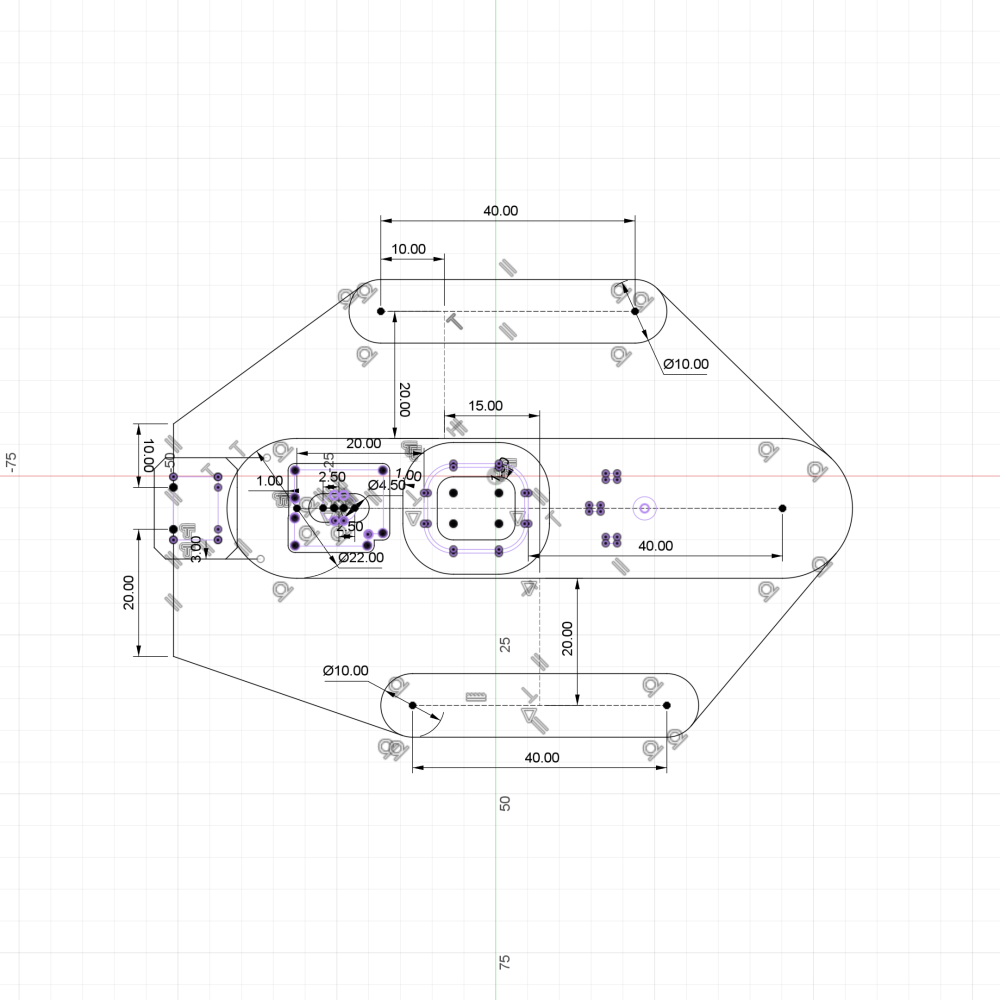

The scanned clay mold is imported into CAD software, where the shape is refined, ensuring it meets ergonomic principles. This step is crucial for adjusting dimensions and smoothing out imperfections. Once the basic shape is established, the upper and lower surfaces are merged using generative design. This method utilizes algorithms to explore various design possibilities, optimizing the structure for comfort and material efficiency.

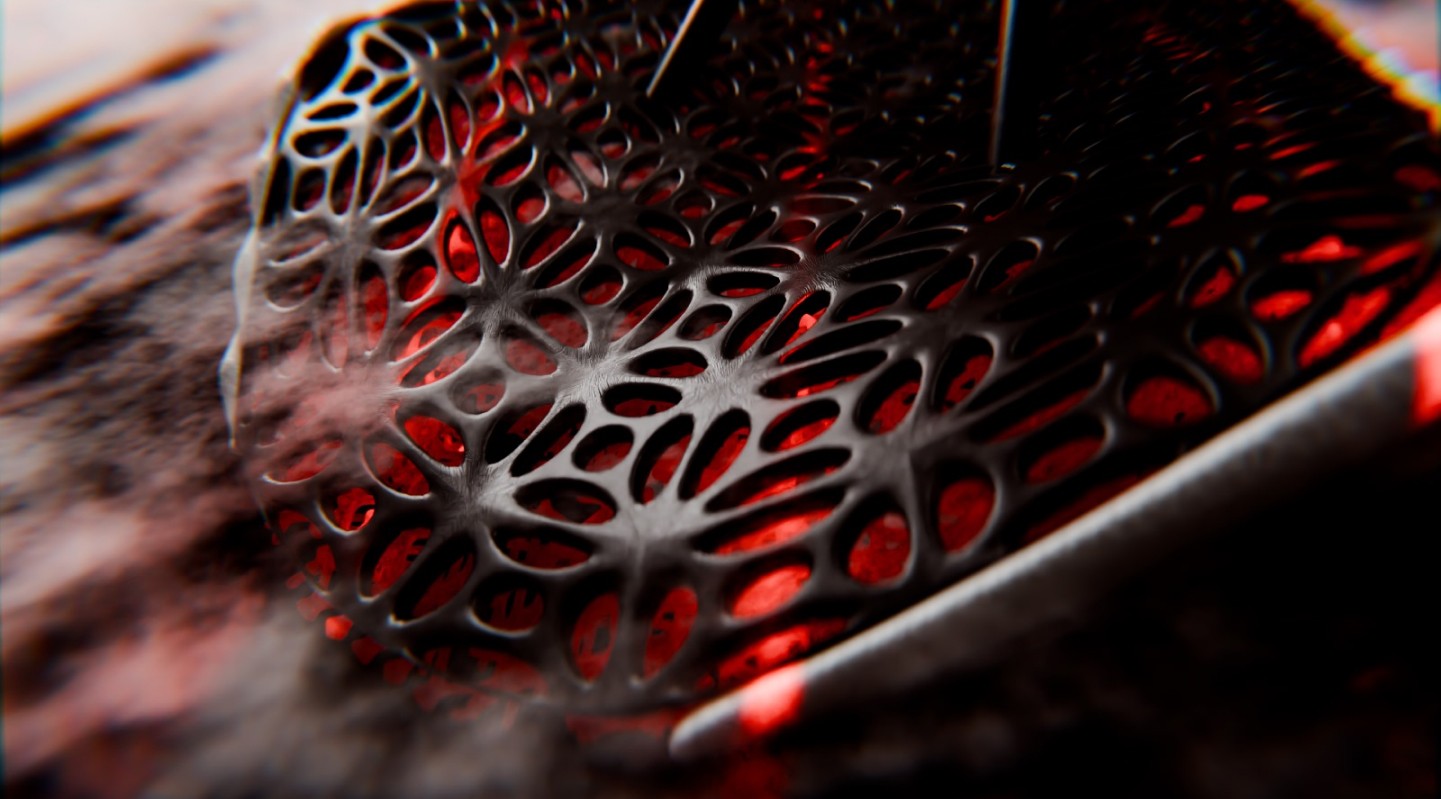

Next, the refined model is imported into rendering software, where the design is brought to life visually. The scene is set with appropriate camera angles and lighting to highlight the mouse's features. Texturing follows, applying realistic materials and colors that replicate the final product. This step is vital for adding depth and realism to the model.

Finally, the process concludes with rendering high-resolution images and creating a short animation to showcase the mouse's design from multiple angles.